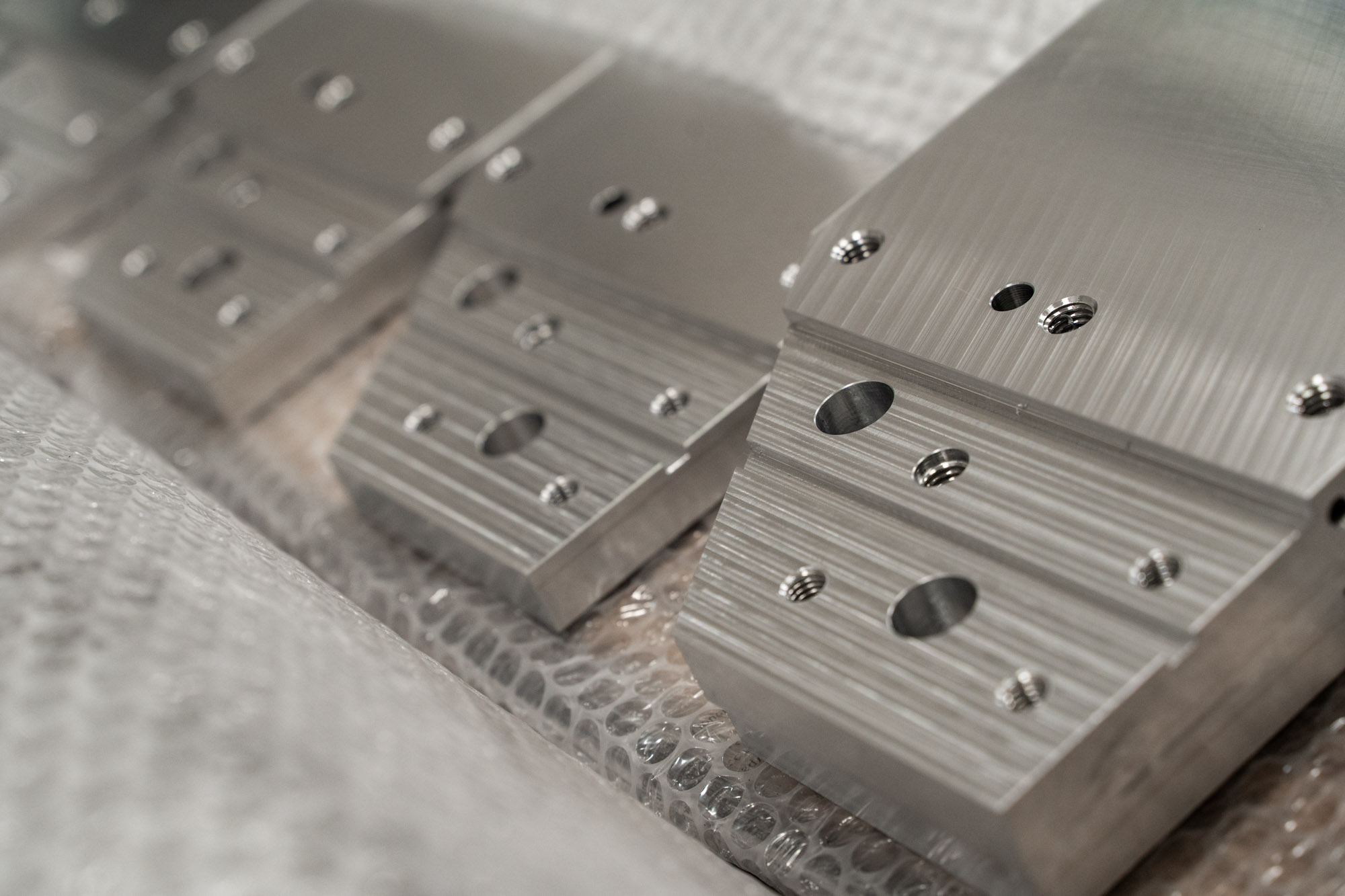

We transform raw plastic polymers into precision components for different sectors.

PLASTIC POLYMERS

From the material to the final product

From prototype design to series production, we are committed to meeting the specific needs of our customers. Plastic polymers can offer remarkable performance when processed paying attention to detail and advanced technology.

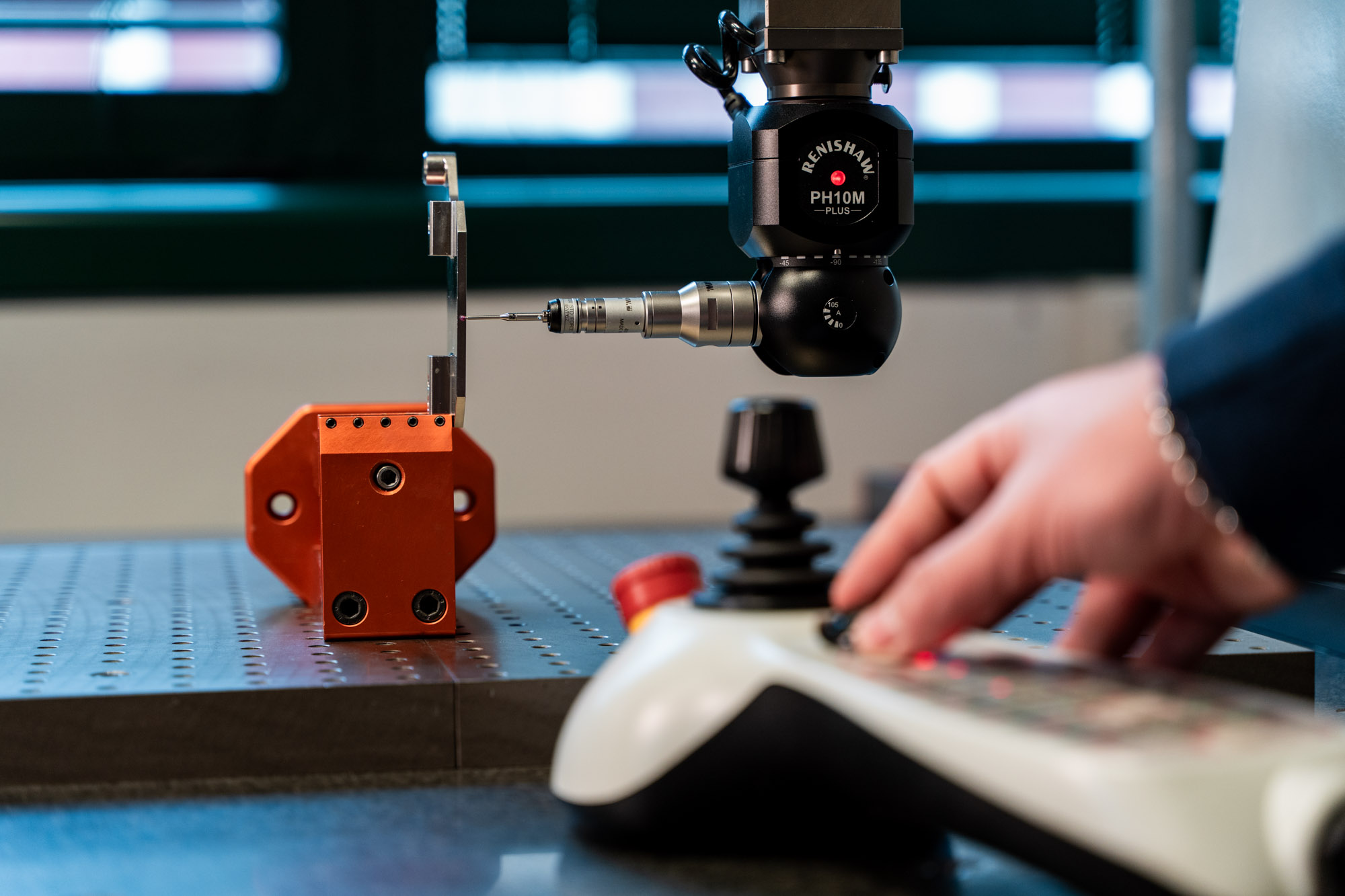

Our components are subject to strict quality controls to ensure compliance with the highest industry standards. Our mission is to provide solutions that customers can count on to improve the performance and quality of their products.

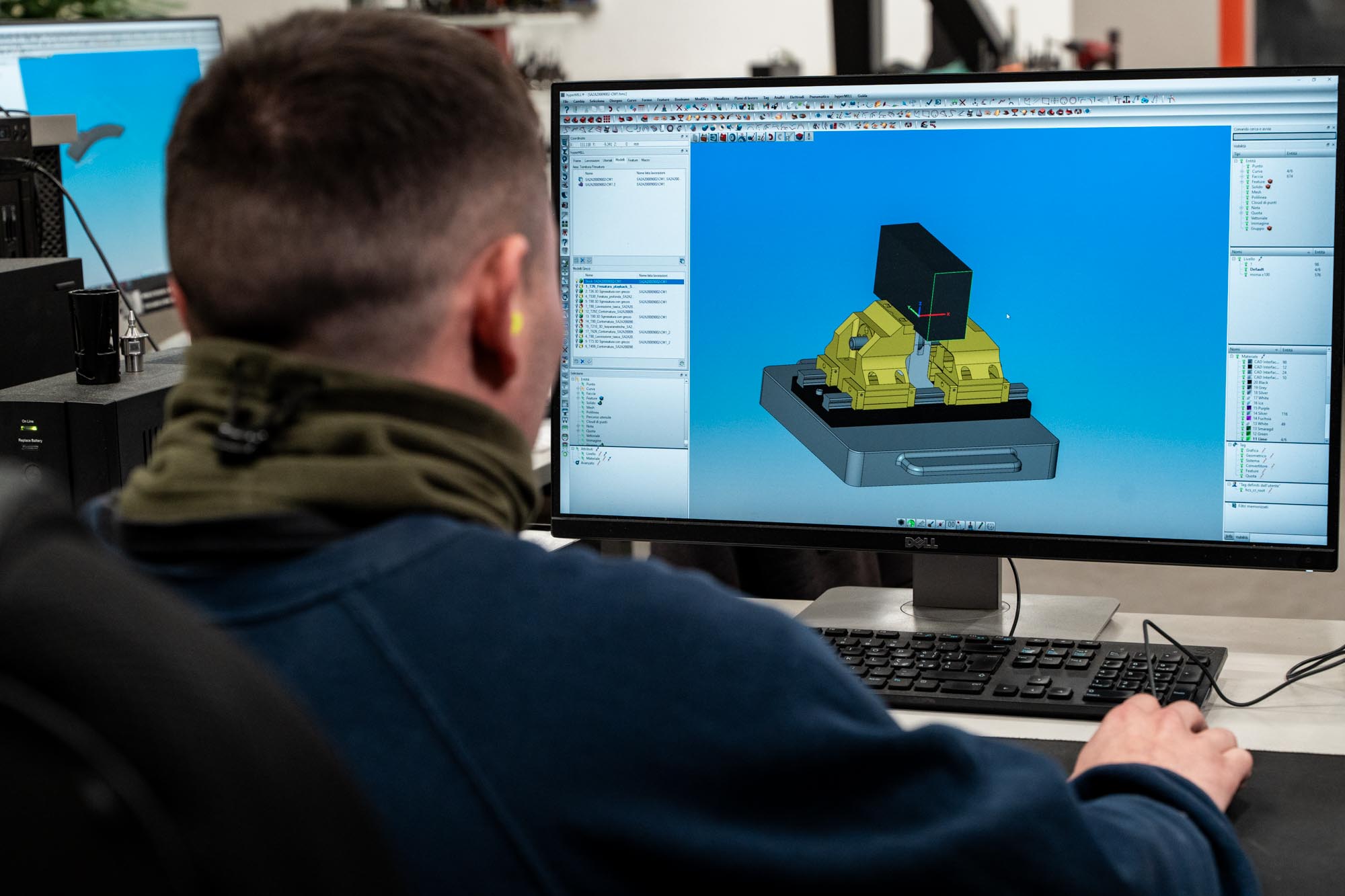

PROTOTYPING

Creativity and technology

Our prototypes are custom designed with the advanced use of CAD software. We create prototypes adapted to specific customer requirements, combining creativity and technological expertise to turn ideas into real solutions.

Production process

AREAS OF INTERVENTION

Our experience in different sectors

CERTIFICATIONS

Certified safety

Our company is certified according to GMP, MOCA quality standards. Our processing for the food industry is compliant with strict regulations and we ensure safety and quality in the mechanical and plastic polymer sectors.

Would you like to have a quote or more information about our services?

Contact us now! One of our experts will be ready

to answer your questions.